PARTS.CAT.COM

FIND PARTS AND RESOURCES TO GET THE JOB DONE

Cat® FLUIDS

|

CAT® COOLANTSELC™ (Extended Life Coolant) DIESEL EXHAUST FLUID (DEF) |

|

CAT® GREASESUtility Greases |

|

CAT® OILS

|

BATTERIES

|

The reliability of your truck and automated equipment begins with a reliable battery. You need to have confidence that your battery will start your equipment every time, even in the most adverse environments and extreme temperatures. The best way to assure your commercial equipment and automotive vehicle will start is to install Cat® Premium High Output, General Service Line or Uninterruptible Power Supply batteries that are manufactured to Caterpillar’s high quality standards. |

Cat® FILTERS

Other brands may technically ‘fit’, but Cat filters protect your engine, drive train, hydraulic systems and components much better over the short, medium and long term. Our specialized design provides maximum filtration efficiency and protection for your Cat machine. So you get more uptime and lower owning and operating costs.

NOT USING CAT FILTERS COULD HAUNT YOU

Your Cat machine performs best with real Cat Parts including filters because all of these components are designed and engineered just for Cat iron. Genuine Cat filters improve performance and protect your engine and hydraulics which means a longer life and higher resale value.

- Increases Injector Life Up To 45% Compared To Competitive Filters

- Decreases Cost Per Hour Up To 80% Compared To Competitive Filters

- Industry’s Thickest Canister Cuts Risk Of System Failure

- Tested 50% Longer Compared to Competitive Filters

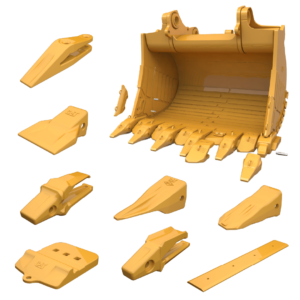

GROUND ENGAGING TOOLS

|

Cat® Ground Engaging Tools (G.E.T.) are the only heavy duty tools engineered with your entire business in mind – built by the industry leader and designed to perform in tandem with Cat® buckets and machines. The result is a ground breaking system optimized for productivity the moment you hit the ground. Choosing the right G.E.T. can make a big difference in your operation’s productivity and profitability. That’s why Caterpillar offers a wide array of integrated ground breaking equipment add-ons built to specific application requirements. Increase your machine productivity by matching G.E.T. products to your specific applications. |

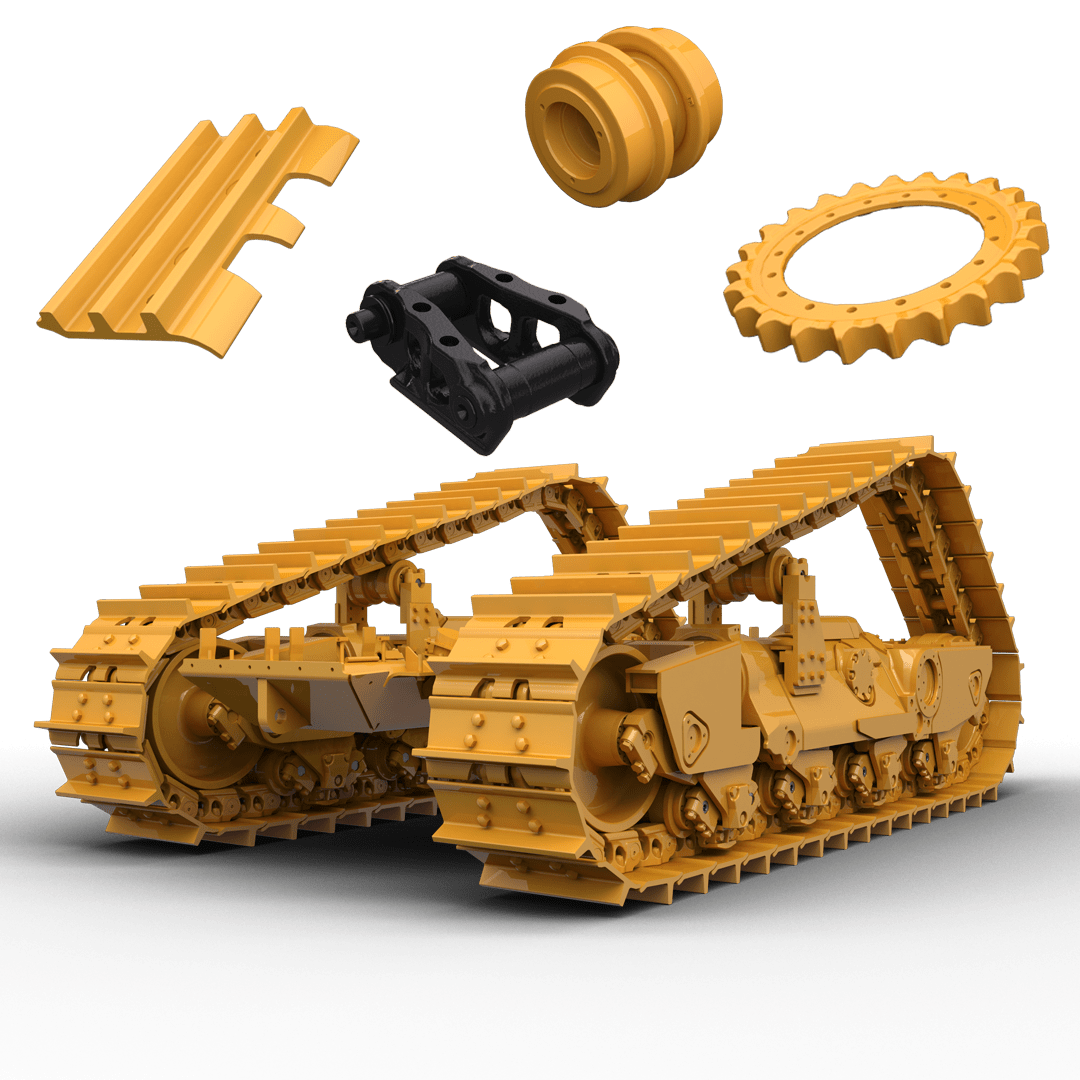

UNDERCARRIAGE

Caterpillar: The Only Original Equipment Manufacturer That Designs and Produces Its Own Undercarriage.

OVER 100 YEARS OF UNDERCARRIAGE INNOVATION

Cat® undercarriage parts work as a powerful system to propel your machine over all types of terrain. Most importantly, we know how to help you get the most from your undercarriage investment. When you consider that 50% of a track-type machine’s owning and operating costs come from its undercarriage, it makes sense to invest in a system that will deliver the most value to your bottom line.

Below are examples of Caterpillar machines we carry undercarriage parts for:

257B, 277B, 287B, 247B, 277C, 941B, D4H, 277, D3B, and D3.

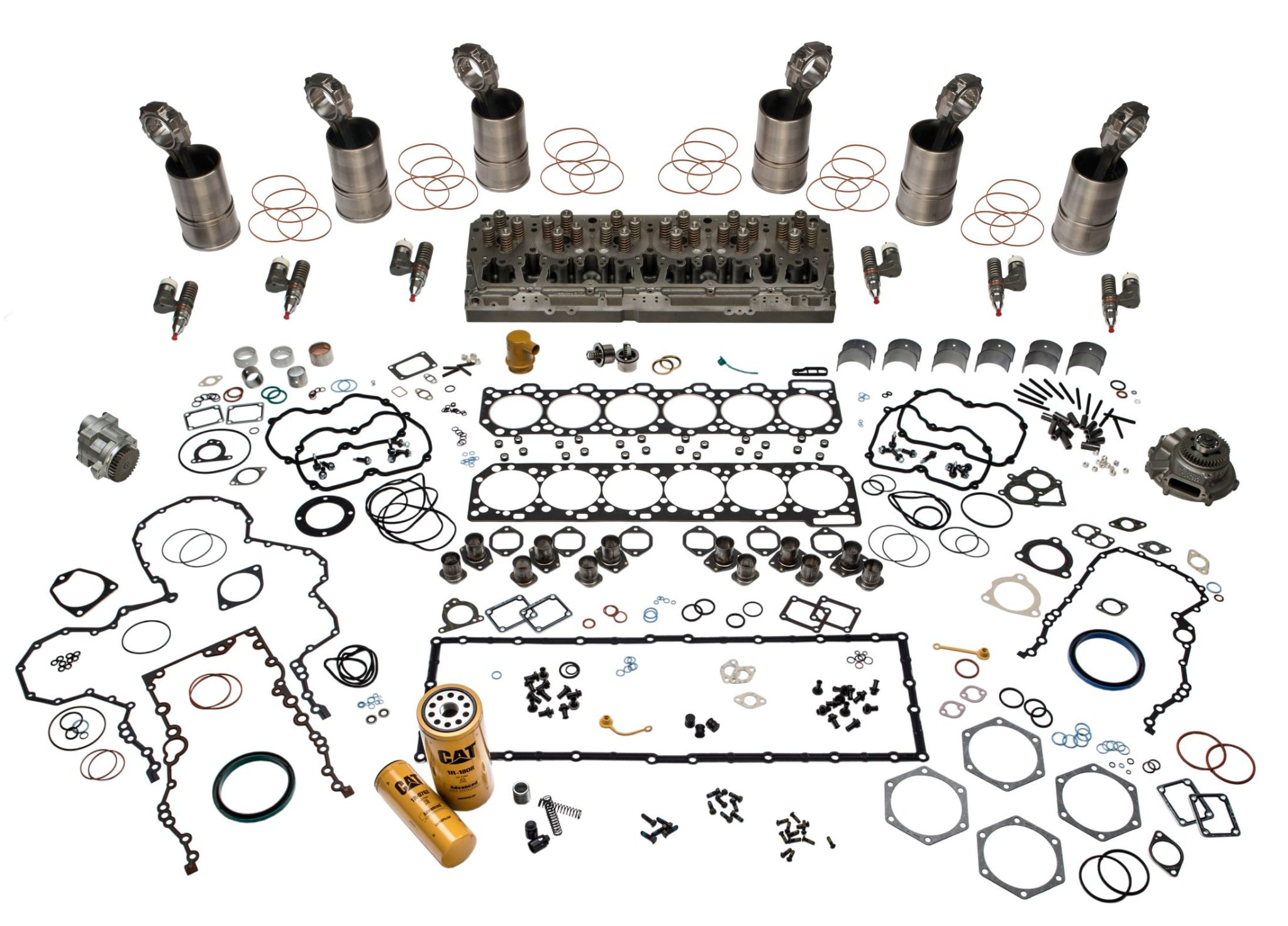

ENGINE PARTS

Guaranteed for fit and function, Cat® Parts offer the right combination of quality and price for your engines. Plus, Cat® Parts provide something that other brands can never match – the total support available at Caterpillar Authorized Service Locations.

SUPERIOR ENGINE PARTS IMPROVE ENGINE PERFORMANCE

Caterpillar knows engine parts must endure incredible stresses and extreme temperatures. That’s why we continually improve design and manufacturing processes.

We want to ensure Cat® engine components work together as a complete system and can be remanufactured for a second life. Test after test identifies critical differences between Cat® engine parts and competitive parts – differences that allow Cat® engine components to improve Engine performance, Increase productivity, Reduce your owning and operating costs

GENUINE CAT® PARTS:

DRIVE TRAIN

Caterpillar designs and manufactures its transmissions and final drive components with these demands in mind. The result is a drive train that lasts longer and works harder over the life of your machine.

Final drive and transmission parts work together to transmit power to the ground and propel Cat® earthmoving equipment through a variety of applications all over the world. Genuine Cat® drive train parts, along with excellent maintenance and repair options, result in maximum productivity and lower owning and operating costs.

Drive train components that must endure:

Incredible torque

High impact loads

Frequent direction and gear changes

DRIVE TRAIN PARTS

- Gears

- Bearings

- Friction Materials

- Transmissions

- Torque Converters

- Drive Shaft

- Differential

- Final Drive

- Brakes

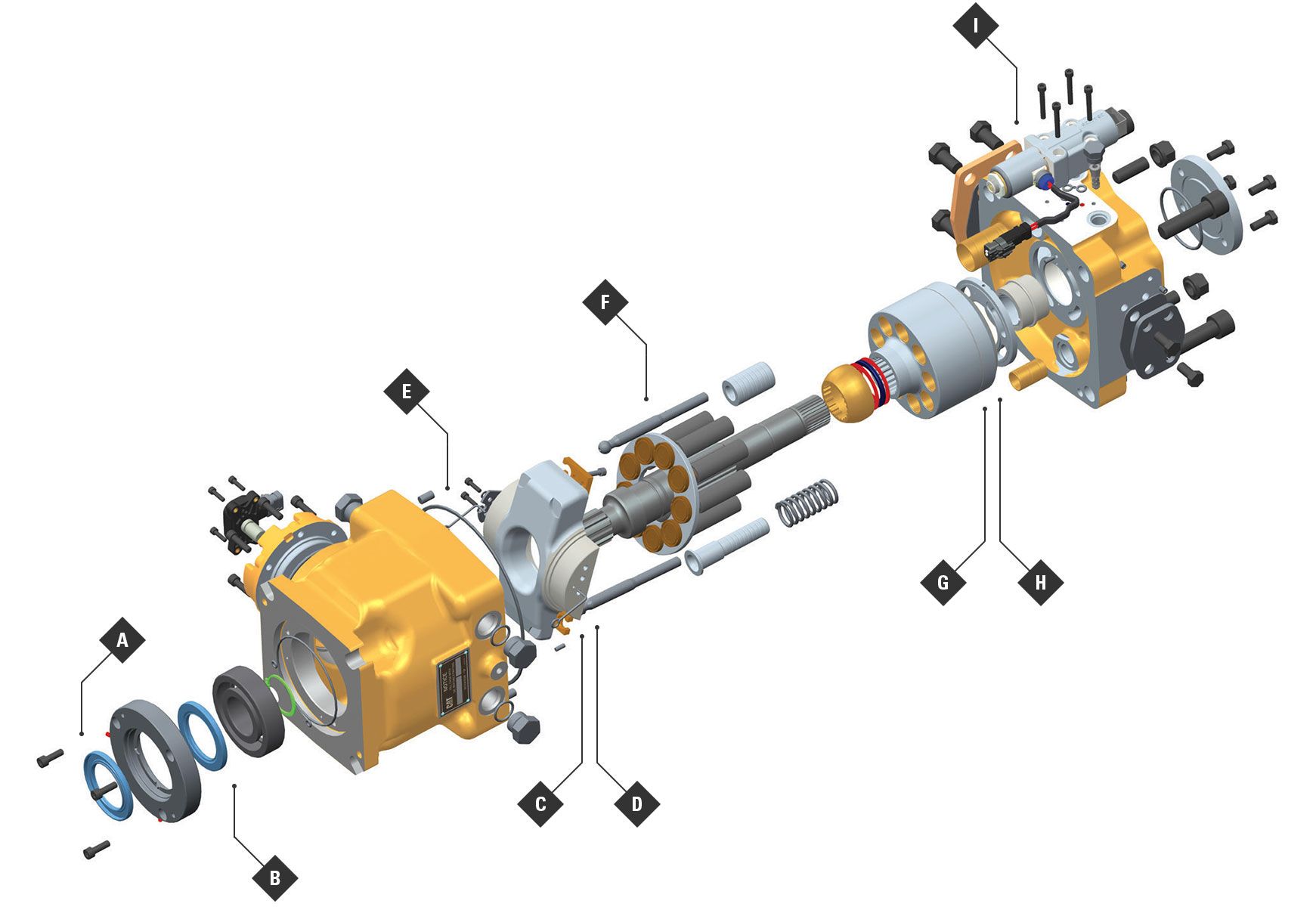

HYDRAULICS

Today’s equipment is hydraulics-intensive. So more and more, the decisions machine owners make about their equipment’s hydraulics directly impact their bottom line.

HYDRAULIC PRODUCTS, SERVICES AND EXPERTISE

Cat® dealers work with hydraulics every day, and have the products, services and expertise to help machine owners make decisions to

- Achieve maximum component life

- Extend oil change intervals

- Keep the hydraulic system running at peak efficiency

- Cut service costs and unplanned downtime.

PARTS EXCHANGE PROGRAM

Partner with Monark for your major component requirements under Parts Exchange (PEx) Program to enjoy minimum repair time and maximum machine availability.

Components under Monark’s Parts Exchange (PEx) Program are remanufactured to like-new Caterpillar specifications following industry-leading safety practices. All components under the program underwent the strictest quality control and the most innovative manufacturing processes in the industry.

- Comprehensive Cleaning and Inspection

- Safe Work Practices

- Strict Quality Management

- Effective Contamination Control

- Latest Product Updates

- Rigorous Testing

- Genuine CAT® Parts